What is the right SSD choice for Embedded systems?

Introduction:

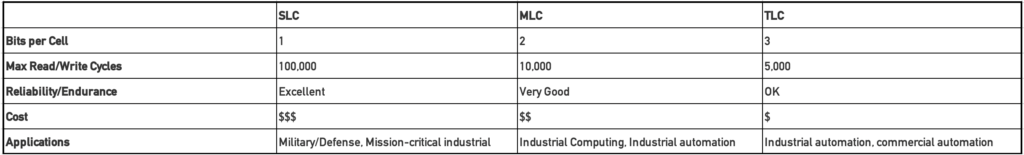

Single-level cell (SLC) and multi-level cell (MLC) Flash memory are similar in their design. MLC Flash devices cost less and allow for higher storage density. SLC Flash devices provide faster write performance and greater reliability, even at temperatures above the operating range of MLC flash devices.

Multi-level cell (MLC) solid state disks (SSDs) strike the right balance for cost, number of read/write cycles, and read/write speed in most embedded system applications.

TLC (like MLC) increases the number of bits per cell. For MLC, you store two bits per cell, which means instead of two voltage states (0 and 1) you have four states (00, 01, 10, 11). TLC takes that a step further and stores three bits per cell, or eight voltage states (000, 001, 010, 011, 100, 101, 110, and 111).

When choosing any technology two things ultimately count most: performance and total cost of ownership. Most people buy products that do what they want done better than alternatives and at a cost to acquire and use that’s favorable versus alternatives. The hard part is deciding how much a higher performance justifies a higher cost or how much a lower cost justifies a lower performance. On the one hand, paying for more performance than you’ll use doesn’t make sense. On the other hand, neither does saving money by not getting the essential performance you would use.

This performance-versus-cost decision gets easier, however, once you realize which of these two variables ultimately counts more. And in the embedded system space, that variable is almost always performance. Having an embedded system that only performs as required “sometimes” is simply not an option when you’re talking about applications like mission-critical rugged application, or industrial control or normal commercial automation.

SLC is still a preference for mission critical military embedded systems

That’s why it’s so important for decision-maker of military embedded systems to realize that buying MLC or TLC SSDs probably means giving up performance their applications need — specifically read/write speed and the number of P/E cycles they can expect over the SSD’s lifetime. A different SSD technology — SLC — is a much better choice. It costs more than MLC/TLC — but offers speed and endurance they can’t match. SLC also specifically suited for rugged mission-critical applications requiring endurance and stability beyond what most rugged applications call for.

MLC seems a good choice between cost and performance

The defining difference between SLC, MLC, and TLC is the number of bits in a single memory cell that can be either on or off when charged. SLC has one bit per cell, MLC has two, and TLC has three. The more bits per cell, the denser (and therefore hotter, hence less reliable) the device. To industrial & embedded applications, MLC can be a good choice between cost and performance. It costs more (but not a lot more) than TLC — but offers speed and endurance TLC can’t match. MLC also costs a lot less than SLC technology

TLC’s significantly fewer cycles limits the technology’s utility to lower-end embedded systems. Unlike slower read/writes, fewer lifetime cycles of TLC SSD is not something you can mitigate by adding cache (which also adds cost). Likewise, SMART (self-monitoring analysis and reporting technology) is an option for mitigating TLC’s shorter MTBF and lifespan. With the development of TLC technology and SSD controller, more and more TLC SSDs are using in industrial Box computer to save cost.

For various of embedded systems, how to select an SSD is not too complicated but requires serious consideration. The two factors are the cost budget and performance/Reliability. It is much easier for a military embedded company to select SLC SSD, at least it should be MLC SSD. For industrial & embedded systems, whichever technology is inherently more reliable, less complex, and faster without mitigation is also usually the less expensive technology for industrial applications.